Pigments in Art and Design: The History and Modern Applications

Home / Single Post

Pigments have played a pivotal role in human history, influencing art, culture, and design across civilizations. From the ancient caves of Lascaux to today’s vibrant digital design palettes, pigments have not only shaped our visual experiences but also offered a window into the evolution of human creativity and technological advancements. This blog post explores the fascinating journey of pigments from their earliest uses in art to their contemporary applications in modern design.

The Origins of Pigments: Ancient Beginnings

1. Prehistoric Art and Early Pigments

The story of pigments begins in the prehistoric era, where early humans used natural materials to create their art. The earliest known pigments were derived from mineral and organic sources. In the Chauvet Cave in France, researchers discovered that ancient artists used ochre, a naturally occurring clay pigment, to create vivid images of animals on the cave walls. These pigments were ground into powders and mixed with water or animal fat to create a paste that could be applied to surfaces.

Ochre, made from iron oxide, produced shades of red, yellow, and brown. Similarly, charcoal was used to create blacks, while manganese and clay provided purples and browns. The use of these pigments not only demonstrates early humans’ artistic abilities but also their understanding of material properties and color mixing.

2. Ancient Civilizations and Pigment Development

As civilizations developed, so did their use of pigments. Ancient Egyptians are renowned for their use of vibrant colors in their art and textiles. They developed synthetic pigments such as Egyptian blue, one of the first artificial pigments created by heating a mixture of silica, lime, and copper. This pigment was used extensively in tomb paintings, amulets, and other artifacts, reflecting its significance in Egyptian culture and religious practices.

The Greeks and Romans also made significant contributions to pigment history. They used natural pigments such as vermilion (from cinnabar) and ultramarine (derived from lapis lazuli). The Romans, in particular, improved pigment production techniques and used these colors in their frescoes and mosaics. The knowledge of pigments was passed down through generations, influencing subsequent cultures and art forms.

Medieval and Renaissance Innovations

1. The Medieval Period

During the medieval period, pigments continued to evolve. The use of vibrant colors in illuminated manuscripts and stained glass windows became prominent. Medieval artisans used pigments derived from minerals and plants, such as indigo for blue and madder root for red. The trade routes of the Middle Ages facilitated the exchange of pigment knowledge and materials across Europe, Asia, and Africa, leading to a broader range of colors and techniques.

One notable development was the use of lapis lazuli, which was ground into the pigment ultramarine. Due to its rarity and cost, ultramarine was reserved for the most important works of art, such as religious paintings and portraits of nobility.

2. Renaissance Advances

The Renaissance period marked a significant leap in the use of pigments. Artists like Leonardo da Vinci, Michelangelo, and Raphael experimented with new techniques and colors, leading to advancements in artistic expression. The discovery of new pigments, such as the synthetic vermilion and the development of oil painting techniques, allowed for greater color saturation and blending.

During this time, artists also began to develop more refined methods for pigment production. The advent of the oil paint medium provided a versatile platform for applying pigments, resulting in the rich textures and depth seen in Renaissance artworks. The creation of new pigments, such as the vibrant greens and blues, expanded the color palette available to artists, further enhancing their creative possibilities.

The Industrial Revolution and Modern Pigments

1. The Industrial Revolution

The Industrial Revolution in the 19th century brought about dramatic changes in pigment production and application. The development of synthetic pigments revolutionized the art and design industries. With advancements in chemistry, artists and designers gained access to a broader and more stable range of colors. Synthetic pigments such as cadmium red, cobalt blue, and chromium oxide green provided vivid, long-lasting colors that surpassed the quality of natural pigments.

The introduction of synthetic pigments also made art supplies more affordable and accessible. Mass production techniques allowed for the creation of standardized paint colors, enabling artists to experiment with a wide range of hues without the limitations of natural pigment availability.

2. Modern Applications and Innovations

Today, pigments are integral to various fields beyond traditional art. Modern applications include:

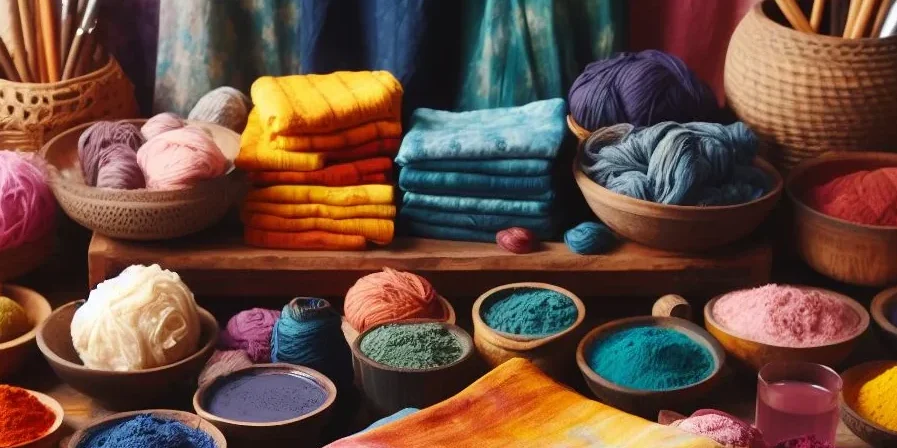

- Textiles and Fashion: Pigments are widely used in the textile industry to dye fabrics and create vibrant patterns. Advances in pigment technology have led to the development of colorfast dyes that maintain their brilliance and resist fading. Pigments are also used in screen printing, sublimation, and other techniques to produce colorful designs on clothing and accessories.

- Graphic Design and Digital Media: In the digital age, pigments play a crucial role in graphic design and digital media. While digital designs are created using RGB (red, green, blue) color models, pigments remain essential for printing processes. The CMYK (cyan, magenta, yellow, black) color model used in printing relies on pigments to produce a wide range of colors in printed materials such as books, magazines, and packaging.

- Architectural Design and Interior Decoration: Pigments are used in architectural coatings, paints, and finishes to enhance the appearance of buildings and interior spaces. Modern pigments offer a range of effects, including matte, glossy, and textured finishes. Innovations in pigment technology have also led to the development of eco-friendly paints that reduce environmental impact.

- Cosmetics and Personal Care: The cosmetic industry relies on pigments to create a wide array of colors for makeup products. From lipsticks to eyeshadows, pigments are formulated to provide rich, vibrant colors while ensuring safety and skin compatibility.

- Art Restoration and Conservation: Pigments play a vital role in art restoration and conservation. Conservators use historical pigments to restore and preserve artworks, ensuring that they retain their original appearance and integrity.

Cultural Significance and Artistic Expression

Throughout history, pigments have not only served functional purposes but also held cultural significance. The choice of colors and pigments often reflects cultural values, beliefs, and aesthetics. For example:

- Symbolism in Color: In many cultures, certain colors hold symbolic meanings. In ancient Egypt, blue and green pigments were associated with fertility and rebirth, while red symbolized power and protection. Similarly, in Chinese art, red is considered a color of good fortune and happiness.

- Ritual and Tradition: Pigments have been used in various rituals and traditional practices. Indigenous cultures worldwide use natural pigments in ceremonial art, body painting, and pottery to convey cultural narratives and spiritual beliefs.

- Artistic Identity: Throughout history, artists have used pigments to establish their unique styles and identities. The choice of pigments and color palettes can define an artist’s work and influence art movements.

The Future of Pigments

As we move forward, the future of pigments promises exciting developments. Advances in nanotechnology and materials science are paving the way for new types of pigments with enhanced properties. These innovations include:

- Nanopigments: Nanotechnology allows for the creation of pigments with nanoscale particles, resulting in more intense and vibrant colors. Nanopigments also offer improved stability and resistance to environmental factors.

- Eco-Friendly Pigments: With growing environmental awareness, there is an increasing demand for eco-friendly pigments. Researchers are developing pigments derived from renewable resources and sustainable processes to reduce environmental impact.

- Smart Pigments: Emerging technologies are exploring smart pigments that change color in response to environmental stimuli, such as temperature or light. These pigments have potential applications in dynamic and interactive design elements.

Conclusion

From the ancient caves of Lascaux to the latest innovations in design, pigments have played a fundamental role in shaping human creativity and expression. Their journey from natural sources to synthetic advancements reflects the evolution of art and design, highlighting their enduring cultural significance and practical applications.

Pigments continue to inspire and influence artists, designers, and creators across the globe. As we look to the future, ongoing advancements in pigment technology will undoubtedly lead to new opportunities and creative possibilities, ensuring that pigments remain at the forefront of art and design for generations to come.

This blog post provides a comprehensive overview of the history and modern applications of pigments, emphasizing their impact on art and design throughout the ages.